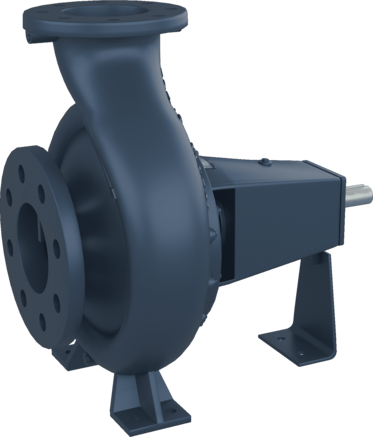

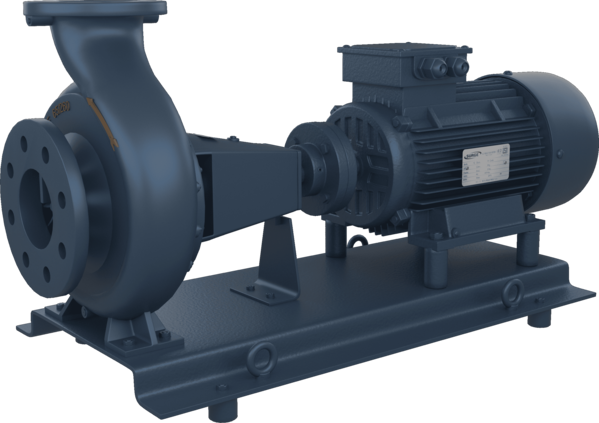

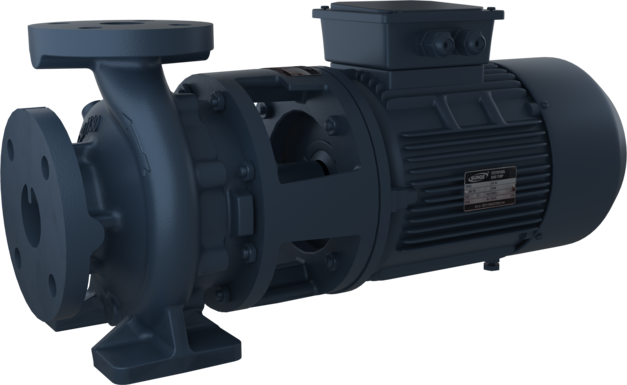

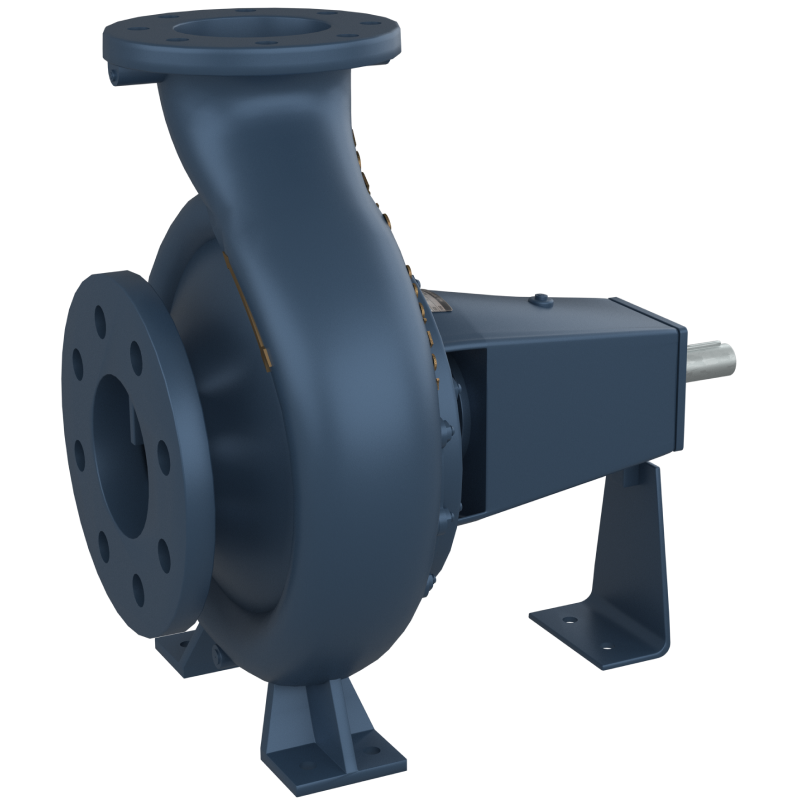

Back Pull Out Pumps (SB Series)

Technical Specifications

| Types | : | Bare Shaft Pumps (Gland & Seal Type) Motor Coupled Pump Sets (Gland & Seal Type) Z Type Bare Shaft Pumps (Seal Type) Z Type With Motor Pump Sets (Seal Type) |

|---|---|---|

| Motor HP (kW) | : | 0.34 (0.25) to 187.74 (140.00) |

| Pipe Size(mm) | : | 50 X 32 to 200 X 150 |

| Speed(rpm) | : | 1450 & 2900 |

| Head(mtrs) | : | Up to 98 |

| Discharge(lpm) | : | Up to 152 |

Applications

- Industry

- Marine

- Cooling Tower

- Engineering

- Irrigation

- Water Circulation

- Water Supply

- Refrigeration

- Fire Fighting Systems

MATERIAL OF CONSTRUCTION

REGULAR SUPPLY

| Pump body (Stem) | : | C. I. Gr. FG 200 |

| Impeller | : | C. I. Gr. FG 200 |

| Neck ring | : | Bronze |

| Stuffing housing | : | C. I. Gr. FG 200 |

| Bearing housing | : | C. I. Gr. FG 200 |

| Shaft | : | SS-410 |

| Shaft sleeve | : | SS-410 |

| Gland packing | : | Graphite asbestos |

| Mechanical seal | : | Carbon ceramic |

| Bearings | : | SKF / Equivalent |

OPTIONAL SUPPLY

| Impeller | : | Bronze |

| Shaft | : | SS-316 (CF 8M) |

| Gland packing | : | Teflone |

FEATURES

- The back pull-out design enables removal of the motor, coupling, bearing housing and impeller without disturbing the pump housing or pipe work.

- These are single stage, single suction, and horizontal shaft type pumps. The pumps are available to operate at 1450 rpm and 2900 rpm at 50 Hz.

- The pump casing is end suction, volute type with top centerline discharge. Suction and discharge nozzles as well as the supporting feet are cast integral with the casing.

- Impeller is enclosed type dynamically balanced. Hydraulic balance is achieved either by back vanes for smaller impellers and by balancing hole with back wear rings for large impellers.

- Shaft is made of high tensile steel accurately machined and ground is supported by anti friction bearings. The shaft is protected by shaft sleeve from wear in stuffing box area.

- The stuffing housing can be sealed by gland packing or by mechanical seal.

- Deep groove ball bearings are provided. Standard lubrication is grease.

- Direction of rotation is clockwise viewed from driving end.

- The pumps are suitable for coupling with electric motors, engines directly or through belt drives.

- Available in bare shaft pump, motor coupled pump and close coupling z type pump design.

APPLICATIONS

- Circulation of water in industries, air conditioning plants, power stations, mine water, lift irrigation, sprinkler systems, booster services, pumping brines, oils etc.

- Drip irrigation, water supply and building services.

- Condensate handling, fire fighting systems, environmental.

- Hot and cold water circulation, cooling water circulation.

- Thermic fluid, jet dyeing, volatile fluids.

- Corrosive and abrasive process chemicals like acids, alkalis, solvents, slurries, hydrocarbons, crystallizing liquids, nitric, ammonia, phosphate, chemical effluents etc.

- Chemicals, petrochemicals, refineries, sugar, paper, laminates.

- Industries, rubber, handling of hydrocarbons, organic and inorganic chemicals, dm water, food industries, salt, textiles etc.