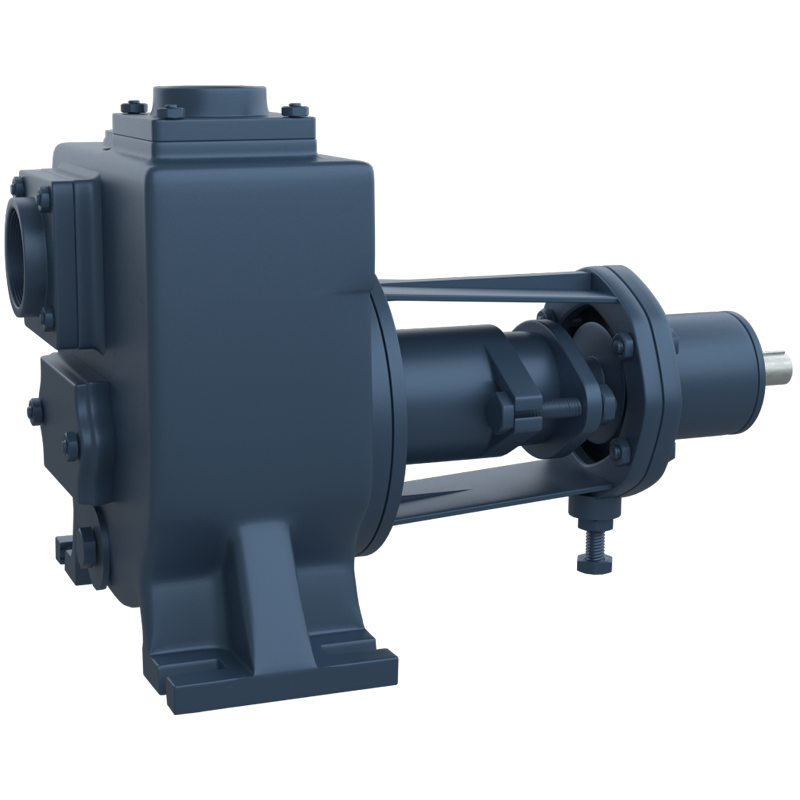

Mud Self Priming Pumps (SEJ Series)

Technical Specifications

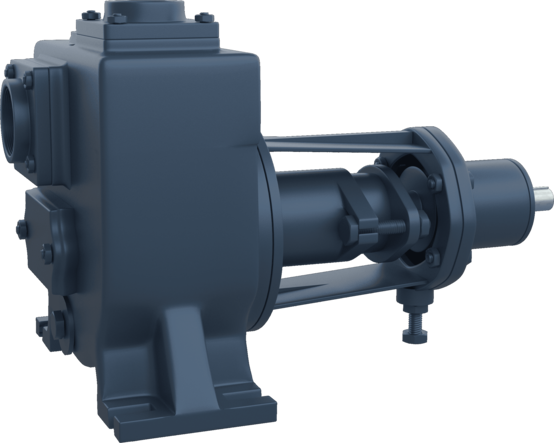

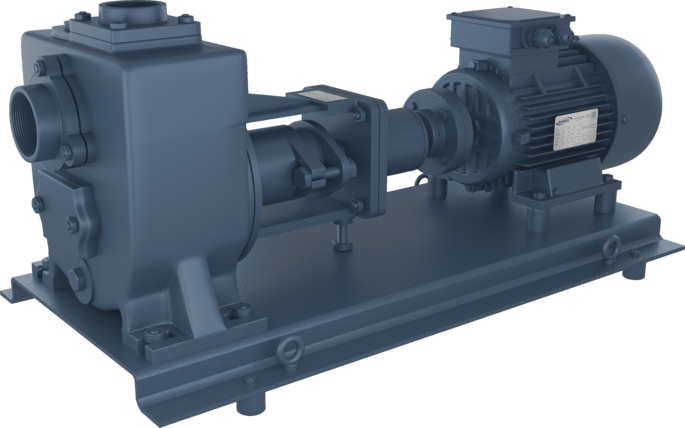

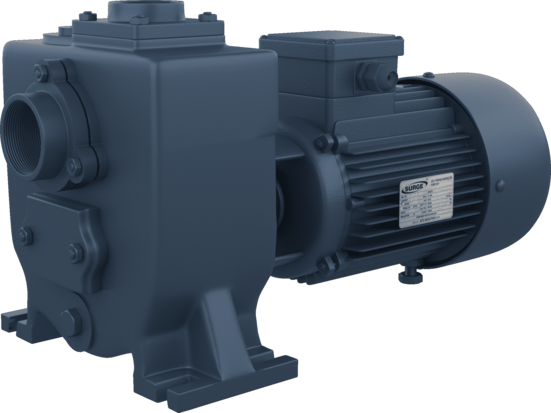

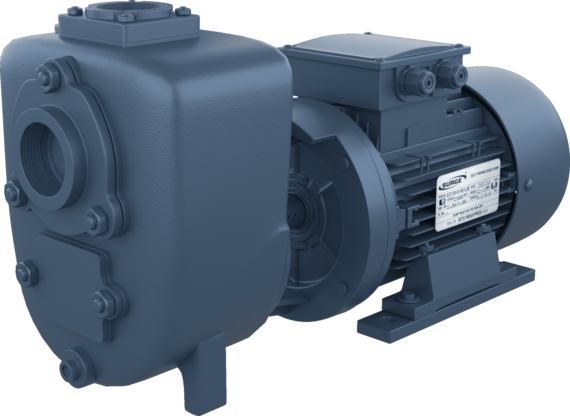

| Types | : | Bare Shaft Pumps (Gland & Seal Type) Motor Coupled Pump Sets (Gland & Seal Type) Monoblock Pump Sets (Gland & Seal Type) Z Type With Motor Pump Sets (Seal Type) |

|---|---|---|

| Motor HP (kW) | : | 0.50 (0.37) to 5.00 (3.70) |

| Pipe Size(mm) | : | 40 X 40 to 80 X 80 |

| Speed(rpm) | : | 1440 & 2800 |

| Head(mtrs) | : | Up to 20 |

| Discharge(lps) | : | Up to 19 |

| Solid Handling Size(mm) | : | Up to 23 |

Applications

- Industry

- Safety

- Civil Engineering

- Marine

- Agriculture

- Mobile Machinery

MATERIAL OF CONSTRUCTION

REGULAR SUPPLY

| Pump / Motor Body | : | C. I. Gr. FG 200 |

| Impeller | : | C. I. Gr. FG 200 |

| Wear Plate | : | C. I. Gr. FG 200 |

| Shaft | : | SS-410 |

| Shaft Sleeve | : | SS-410 |

| Stamping | : | CRNGO, M-45 Grade |

| Gland Packing | : | Graphite asbestos |

| Bearings | : | SKF / Equivalent |

OPTIONAL SUPPLY

| Impeller | : | SS-316 (CF 8M) / Bronze |

| Wear Plate | : | SS-316 (CF 8M) / Bronze |

| Shaft | : | SS-316 (CF 8M) |

| Shaft Sleeve | : | SS-316 (CF 8M) |

| Gland Packing | : | Teflon |

FEATURES

- Compact design and efficient performance.

- Rapid self-priming without foot valve. Once filled with water, the pump is automatically primed to a height of 7.5 meters.

- Easy maintenance and spares availability.

- Open impeller design allowing the passage of wide solid bodies and easy inspection.

- Long product life due to the parts subject to wear can be easily replaced several times to restore the original performance of the pump.

- All rotating parts are dynamically balanced for smooth running and low vibration.

- Only the suction pipe needs to be immersed in the liquid. The pump can be located above and in a dry place, in the most suitable location for service and control. Hence the pump is easy to install.

- Motor designed for wide voltage fluctuation for monoblock pump sets.

- From 180 to 240 volts for single phase pumps and From 350 to 450 volts for three phase pumps.

- All pumps are available with gland packing or mechanical seal.

- Available in bare shaft pump, monoblock pump, motor coupled pump.

APPLICATIONS

INDUSTRY

- Transfer clean, dirty, containing sand in suspension, muddy, neutral, alkaline, acidic liquids, low viscous petroleum products, solvents even if dirty, milk of lime, caustic soda etc.

- Washing, cooling, recirculation, smoke scrubbing.

- Treatment pumping polluted, hot or corrosive waste water containing sand, mud or solids in suspension, dosing neutralizing liquids, pumping out settled sludge.

AGRICULTURE

- Surface irrigation, liquid manure oxygenation, transfer and spraying liquid manure or fertilizers, distribution of liquid animal feed, transfer of must, washing.

SAFETY

- Drainage after flooding or torrential rains.

- Emergency duty temporary sewage pumping, fire fighting, recovery of dangerous liquids.

CIVIL ENGINEERING

- Drainage of excavations, canals or ponds.

- Ground water dewatering with drains.

- Water supply from wells or canals.

- Washing concrete castings and aggregate.

- Recirculation of bentonite and drilling mud.

- De watering foundation, trenches and pits.

MARINE

- Loading and unloading, bilge pumping, washing, fire fighting, stripping, sanitary duty and circulation.